A food manufacturing company was sentenced at the Christchurch District Court after a worker had their thumb severed while cleaning a machine used to blend products

Wimpex Limited was fined $240,000 following a WorkSafe investigation, which found Wimpex Limited, did not have adequate guarding in place. An initial fine of $270,000 was reduced due to the company’s financial situation.

Wimpex carried out checks on the electrical componentry of the machine when it first arrived in New Zealand. However, no other assessments were carried out.

Head of Specialist Interventions Simon Humphries said the incident highlights the importance of conducting effective risk assessments and safe guarding machines to industry standards.

“The machine should have been guarded and the worker’s training should have included safe work instructions for clearing jams and cleaning when the guard had to be opened.

“This incident could have been easily avoided if the machine was guarded adequately.”

- A fine of $240,000 was imposed.

- The company was sentenced under sections 36(1)(a), 48(1) and (2)(c) of the Health and Safety at Work Act 2015.

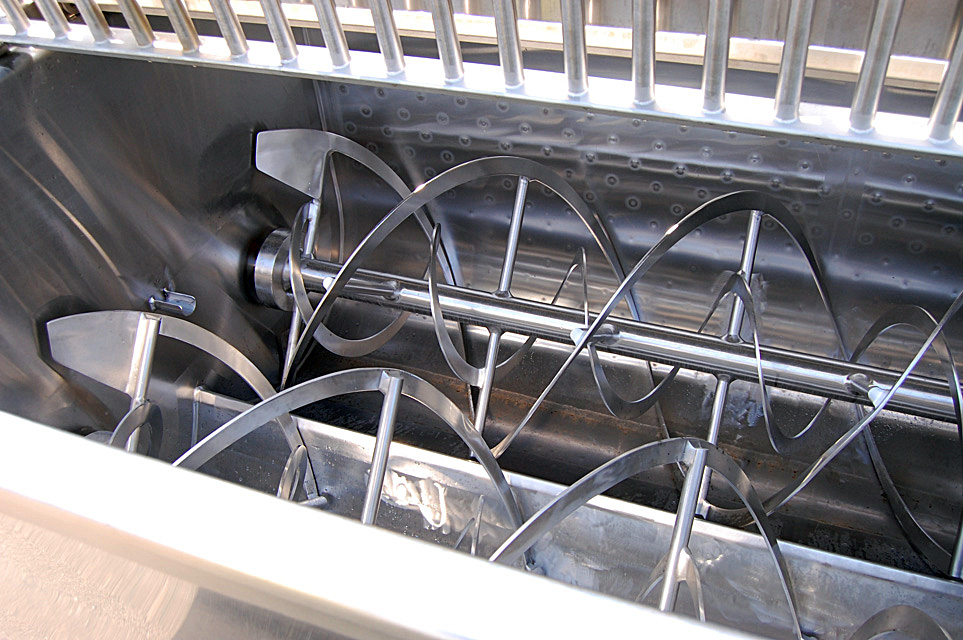

- Being a PCBU, failed to ensure, so far as was reasonably practicable, the health and safety of workers who work for the PCBU, while the workers are at work in the business or undertaking, namely while operating, including cleaning, the Dahepak Auger Machine 2S-5, did fail to comply with that duty, and that failure exposed the workers to a risk of serious injury arising from being cut or entrapped by an inadequately guarded rotating auger.

- The maximum penalty is a fine not exceeding $1,500,000.

This follows another incident where a toilet paper manufacturer was sentenced after a worker was crushed, also due to inadequately guarded machinery. This further highlights the importance of having machinery that has been properly guarded and meets industry standards.